Running a factory is like juggling flaming torches while riding a unicycle. You’re chasing efficiency, cutting costs, and hoping machines don’t pick the worst moment to throw a fit. Digital twins are your trusty co-pilot, offering a virtual window into your operations to predict issues, test ideas, and save serious cash. From winning project bids to streamlining production, here’s how they’re making life easier for anyone in industrial automation.

What a digital twin really means in manufacturing today

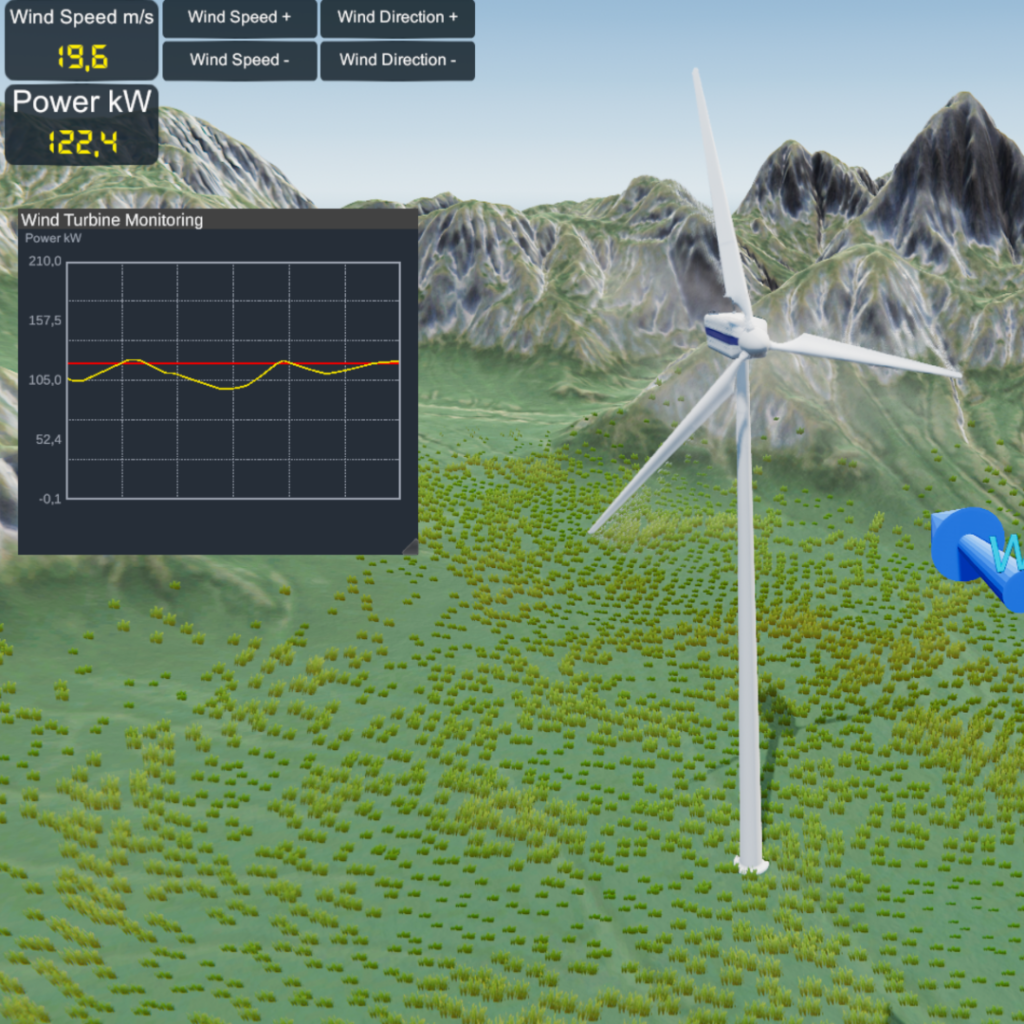

A digital twin isn’t just a shiny 3D model or a dashboard you glance at over coffee. It’s a living, breathing virtual version of your factory, product, or process, powered by real-time data from sensors, PLCs, and SCADA systems. It mimics everything—mechanical movements, software logic, even that one robot’s quirky habits.

Think of it as a virtual playground where you can experiment, spot problems, and optimize without touching a single bolt. Tools like Machines Simulator make this easy, letting you create interactive 3D simulations with realistic physics and behavior, so you can test and tweak without a tech meltdown.

Why Digital Twins are gaining traction in industrial plants

Faster response to failures and unplanned stops

Nothing hurts like a production line stopping because a machine decided it’s time for a siesta. Downtime can cost thousands per hour, but digital twins act like a crystal ball, spotting trouble before it strikes. By analyzing live data, they help you move from “oh no, what now?” to “yep, we’ve got this,” scheduling fixes before chaos hits.

Reducing waste and improving resource efficiency

Wasting materials or energy is like tossing money out the window. Digital twins let you run “what-if” scenarios to find inefficiencies—say, where you’re burning too much power or overusing raw materials. You can optimize cycle times, streamline workflows, and even lower your environmental footprint, making your factory leaner and greener.

Winning bids and validating specs early

Here’s where digital twins really shine: early project phases. When pitching a bid, why show a boring 2D drawing when you can wow clients with a 3D simulation? You can also validate project specs—cycle times, production rates, cadences—before anyone picks up a tool. It’s like rehearsing a blockbuster movie to nail the premiere.

Real examples of Digital Twins applied in production

Robotics and automotive line optimization

Automotive giants like BMW and Tesla use digital twins to orchestrate their robotic assembly lines. They test every move virtually, ensuring parts fit and function perfectly before hitting the factory floor. It’s like a dress rehearsal for robots, cutting setup time and costly errors.

Process control in chemical and energy sectors

In high-stakes fields like energy or chemicals, one wrong move can spell disaster. Digital twins simulate complex interactions—temperature, pressure, chemical reactions—so you can optimize processes safely. It’s like practicing a high-wire act in a virtual world first, ensuring safety and efficiency.

Virtual commissioning for flawless programming

Digital twins are MVPs in virtual commissioning, letting you validate and test programming before touching real equipment. Automation teams can start coding earlier, test logic in a safe environment, and catch bugs before they haunt the shop floor. This saves hours of mechanical design and prevents costly rework.

Tangible benefits that go beyond dashboards

Faster product validation before physical deployment

Gone are the days of endless physical prototypes. Digital twins let you test products, processes, and designs virtually, slashing weeks off your timeline. It’s like hitting the fast-forward button on innovation, getting you from concept to reality in record time.

Predictive actions based on live machine behavior

Pair a digital twin with IoT and machine learning, and you’ve got a system that watches your machines like a hawk. Spot a glitch? You’ll get an alert—or even an automatic fix—before it tanks your quality or spikes your energy bill. This keeps your operation smooth and your budget happy.

Cost and time savings from day one

Using a digital twin early—like during the offer phase—means fewer hours spent on mechanical design. Your programming team can jump in sooner, validating code before the real gear arrives. Plus, you can simulate different scenarios to avoid expensive mistakes, like picking the wrong layout or missing a bottleneck.

What makes a digital twin work at scale

Combining sensor data with PLC and SCADA

A digital twin lives on data, but pulling it from IoT sensors, legacy PLCs, and SCADA systems can feel like herding cats. Robust middleware and edge computing are your allies, ensuring real-time processing without lag. Modern platforms simplify this, making integration less like a tech wrestle and more like a smooth handshake.

Building the simulation layer with 3D and logic

3D CAD models are the skeleton, but the brain comes from simulating machine logic, material flow, and production quirks. Advanced twins use physics-based models to mimic real-world chaos, so you’re ready for anything. Machines Simulator’s flexible framework lets you customize these behaviors easily, adding realistic dynamics without needing a coding wizard on speed dial.

Visualizing performance through VR/AR Tools

Want to step inside your factory from your desk? AR/VR-enhanced digital twins make it happen, perfect for training, maintenance, or wowing clients. Imagine troubleshooting a machine virtually or training new hires without risking real equipment—it’s like giving your team superpowers, no cape needed.

Common roadblocks in implementation

Data trapped in legacy systems

Many factories run on systems older than your favorite 90s band. Getting data out of these relics is a pain, but modern integration tools can bridge the gap, pulling info from even the dustiest setups so your digital twin doesn’t miss a beat.

Security, access control, and data ownership

More connections mean more risks. Cybersecurity is like locking your digital front door—you need tight access controls to keep things safe. Proper data governance ensures your twin stays secure and your proprietary info doesn’t end up in the wrong hands.

Operational resistance and lack of technical training

New tech can spook even seasoned pros. Some might dig in their heels, worried about learning curves. The fix? Show quick wins—like catching a fault before it costs a fortune—and offer hands-on training. Early successes and clear demos can turn skeptics into believers.

What’s next for digital twins in manufacturing?

Digital twins are just warming up. Picture AI making predictions sharper than a chef’s knife, supply chains syncing like a perfect playlist, and AR/VR turning remote work into a sci-fi dream. The real game-changer? Digital twins are evolving into a complete value chain for engineering projects, running factories, and training the next generation in automation and control. They’ll connect departments, processes, and systems that don’t yet play nice, creating factories that are efficient, resilient, and sustainable.

Curious about bringing this vision to your operations? Explore more at Nirtec and see how digital twins can transform your factory, one virtual step at a time.